Today’s concrete pumps are mostly positive displacement pumps. The operator sets the volume control level and automatically gets a set output; but the variable is the pressure. Under normal circumstances, the mix pumps easily and the pressures are low. When there is a plug or a difficult-to-pump mix, the pump increases the pressure instantly to keep the same output the operator requested. When an unexpected plug occurs, the sudden increase in pressure by the pump can cause a violent surge in the system or burst a pipe that has worn to the point that it cannot contain the pump’s maximum pressure setting.

Concrete pumps generally have two pressure ratings for concrete pumping line pressure. Most concrete pumps are shipped from the factory pre-set to the lower pressure setting, which has the pump applying the hydraulic force to the rod side of the differential cylinders. Because there is less surface area for the hydraulic fluid to engage, this setting pushes the differential cylinders faster, giving the concrete pump more strokes per minute and a greater output rate.

In high-pressure models, or if switching the pump to the higher-pressure setting on standard models, the hydraulic pumps apply pressure to the head side in the differential cylinders. Due to the engagement with the maximum surface area, more hydraulic force is applied to push the cylinders harder and create a greater working line pressure. The tradeoff is fewer strokes per minute and a lower output rate.

Most industry professionals define high-pressure concrete pumping as delivery line pressures exceeding 85 BAR / 1233 PSI. The average boom pump truck on its lower pressure setting is 85 BAR / 1233 PSI. A majority of these boom pump trucks can also be set on high pressure at an average of 130 BAR / 1885 PSI. Trailer-mounted and truck-mounted concrete pumps have their own unique concrete delivery line pressures. It is important to check your owner’s manual or machine tag to confirm the concrete delivery line working pressure of your machine.

The concrete pumping standards, ASME B30.27 for the U.S. and CSA Z151 for Canada (as well as most concrete pump owner’s manuals), state that all delivery system components attached to your concrete pump must meet or exceed the working pressure of the concrete pump.

Pumping at high pressure requires more attention to your delivery system. All your delivery system line components and connection clamps must be rated higher than your concrete pump’s delivery working pressure. If your delivery system is rated lower than your concrete pump’s working pressure, you may experience a sudden failure of your delivery system, potentially causing severe injury, property damage, or even death.

When pumping long distances, the concrete delivery line pressure will decrease as you get farther away from the pump. The exact change in delivery line pressure varies with the delivery line setup, concrete mix design, and even pumping speed; system pressure can be tested with the proper instruments. . A hazardous situation arises if the delivery line becomes plugged. The delivery line from the plug back to the pump will become pressurized, at or near the maximum delivery line pressure.

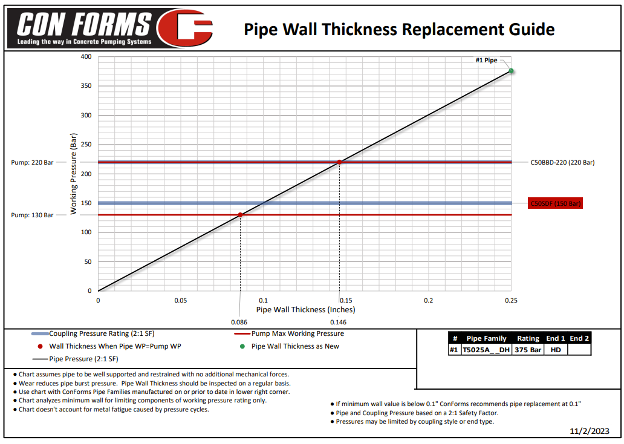

All delivery systems should be labeled with their maximum working pressure. This rating is the maximum pressure the item can hold at a 2:1 working pressure when new. As concrete delivery system pipes, bends and hoses are used, they wear and become thinner. The delivery system will be capable of holding less and less pressure as it wears. It is important to inspect and evaluate your delivery system. Consult your delivery system supplier to get minimum thicknesses for the working pressures of the pump being used and replace all worn components that test lower than the minimum value. It is important to note that if any component in your delivery system is rated lower than the rest of your delivery system, then your entire delivery system is rated at the lower pressure value.

The X-axis on the chart indicates the delivery line thickness. The Y-axis shows the working pressure. The pressures capable of a specified concrete pump are shown in red on the chart. The clamps for the project are also represented by the blue line on the chart. The diagonal line represents the pipe selected for the project. The chart shows that one clamp selected meets or exceeds both pressure settings for the pump. One of the clamps that is highlighted in red will not be safe if used on the pump’s higher pressure setting as it does not meet or exceed the higher pressure requirements. The pressure and the line thickness intersect and give us the minimum thickness for both pressure settings. If the pipe thickness drops below this thickness, it will not be safe at a minimum of a 2:1 safety factor.

If you have any questions regarding pressure or minimum thickness values for your delivery system, please contact your delivery system supplier.