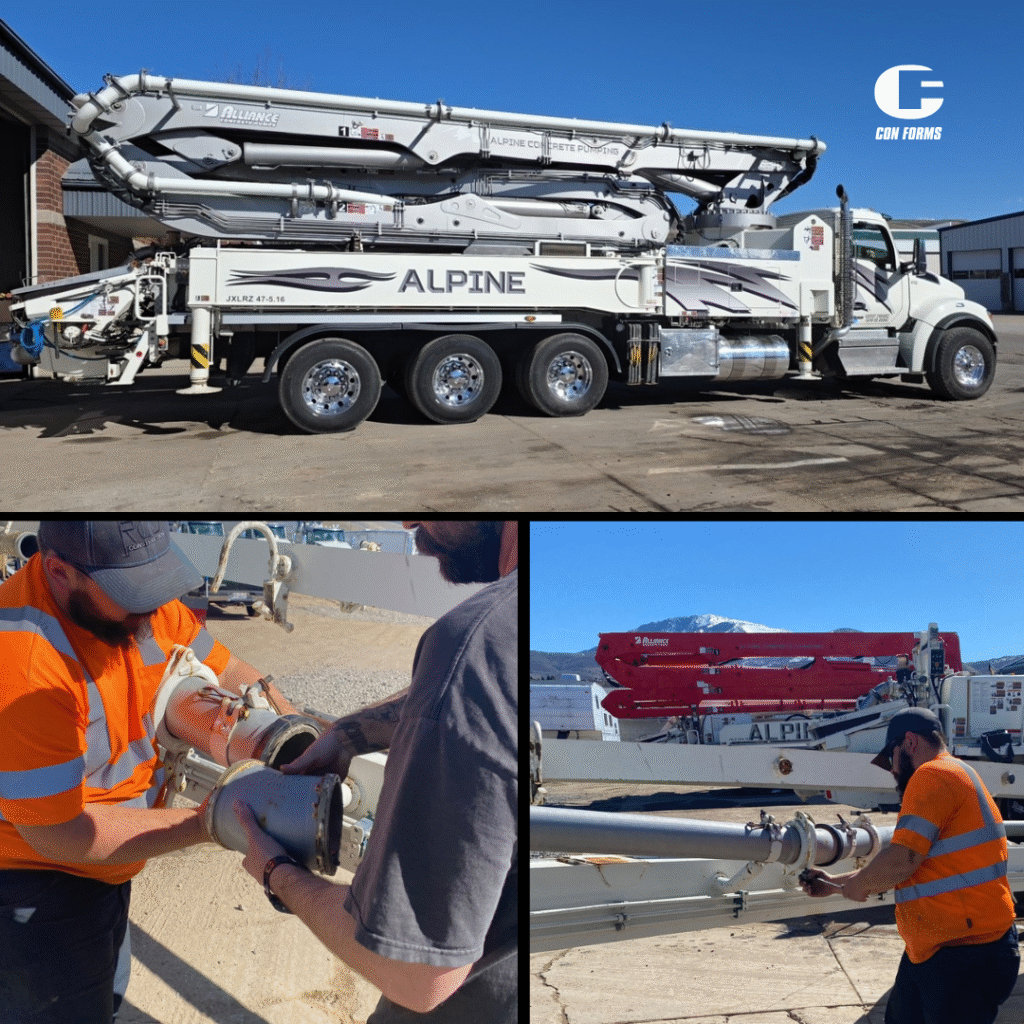

At the request of Jamie Harvey, owner of Alpine Concrete Pumping (Morgan, UT), Con Forms’ Michael Cetnar recently conducted an in-depth pipe inspection training session with Alpine’s boom pump operators. The goal was to reinforce best practices and ensure optimal safety and performance in their concrete delivery systems.

During the session, Michael emphasized that every boom pump has high-wear areas, and identifying these zones is critical for maintaining system integrity. Operators were shown how to rotate pipe and bends to extend the lifespan of their equipment and reduce unnecessary wear.

He also highlighted the importance of verifying pipe measurements against manufacturer-supplied drawings. This step helps prevent ordering incorrect lengths and ensures that bends are properly matched to both the pump and the schematics.

Another key topic was recognizing signs of pipe wear and understanding the minimum wall thickness standards for the pipes used on Alpine’s boom trucks. Operators were encouraged to perform routine visual inspections, especially when components like elbows or gaskets are removed or replaced.

The group discussed the value of inspecting adjacent components whenever changes are made—whether it’s swapping out a gasket, adding a boom reducer, or changing the tip hose. Operators were trained to look for early warning signs of system issues and were reminded: “If in doubt, bring it to a manager or supervisor.”

In today’s digital age, Michael also encouraged the use of video calls or photo sharing to quickly clarify any uncertainties about equipment condition.

Con Forms appreciates Alpine’s commitment to safety and maintenance excellence, and we’re proud to support their team with the knowledge and tools to keep their systems running smoothly.