This specially formulated commercial primer from Con Forms prepares the inside walls of your steel pipes, elbows, reducers, and rubber hoses for today’s harsh concrete pumping mix designs. It coats the surface of the inside wall with a super-slick membrane layer that the day’s first batch of concrete glides over when initially filling the entire line, preventing power-robbing friction from creating early blockages or material build-up.

Prepare for your long day of harsh mixes delivered by late cement mixer trucks by starting everything right by sliming the insides of your pipeline with the engineered coating that works.

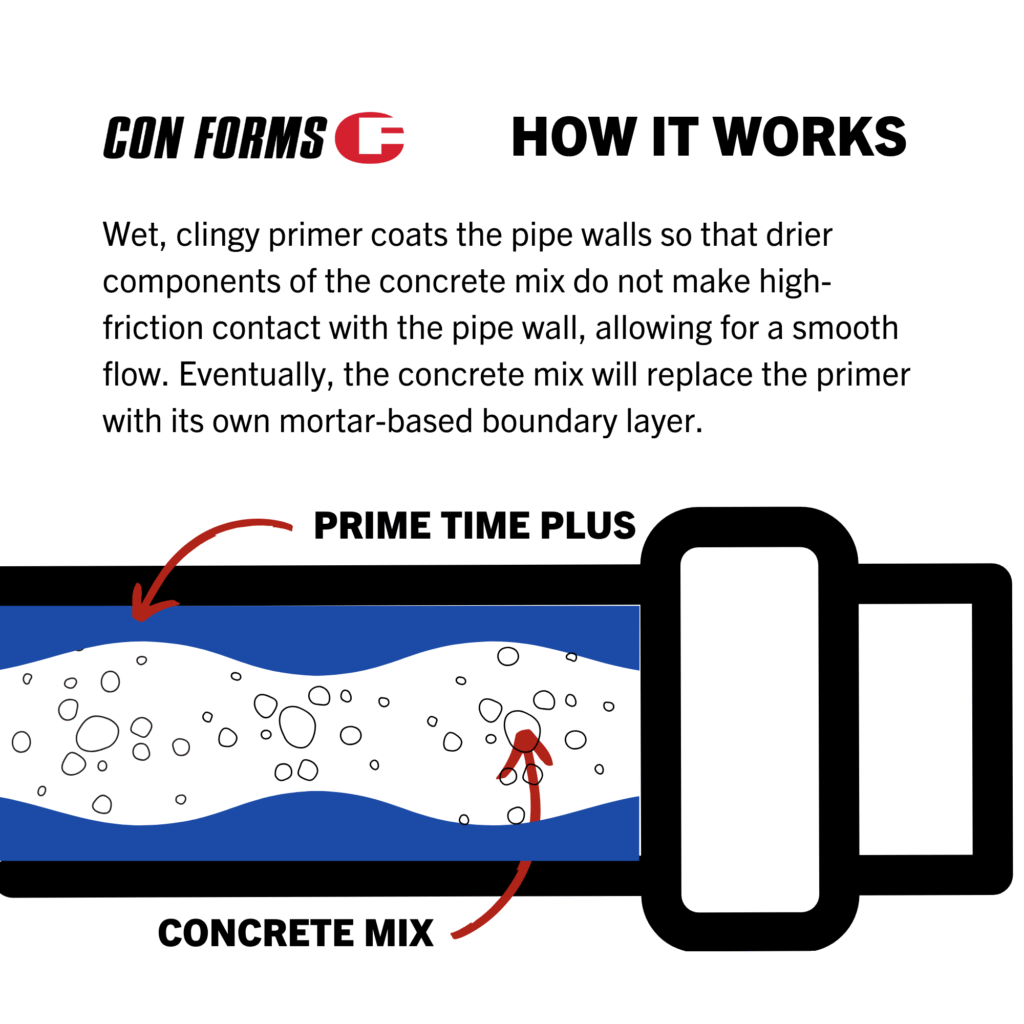

By pre-coating the walls of the pipeline components with a wet, slippery, and clingy film, the drier components of the concrete mix that initially move through the pipe are not able to penetrate and make contact with the pipe wall. By avoiding this high-friction contact, the mix moves smoothly through the pipes and sets up the pumping flow that will be needed for the rest of the day. Eventually, the concrete mix will replace the PRIME TIME PLUS layer with its own mortar-based boundary layer.

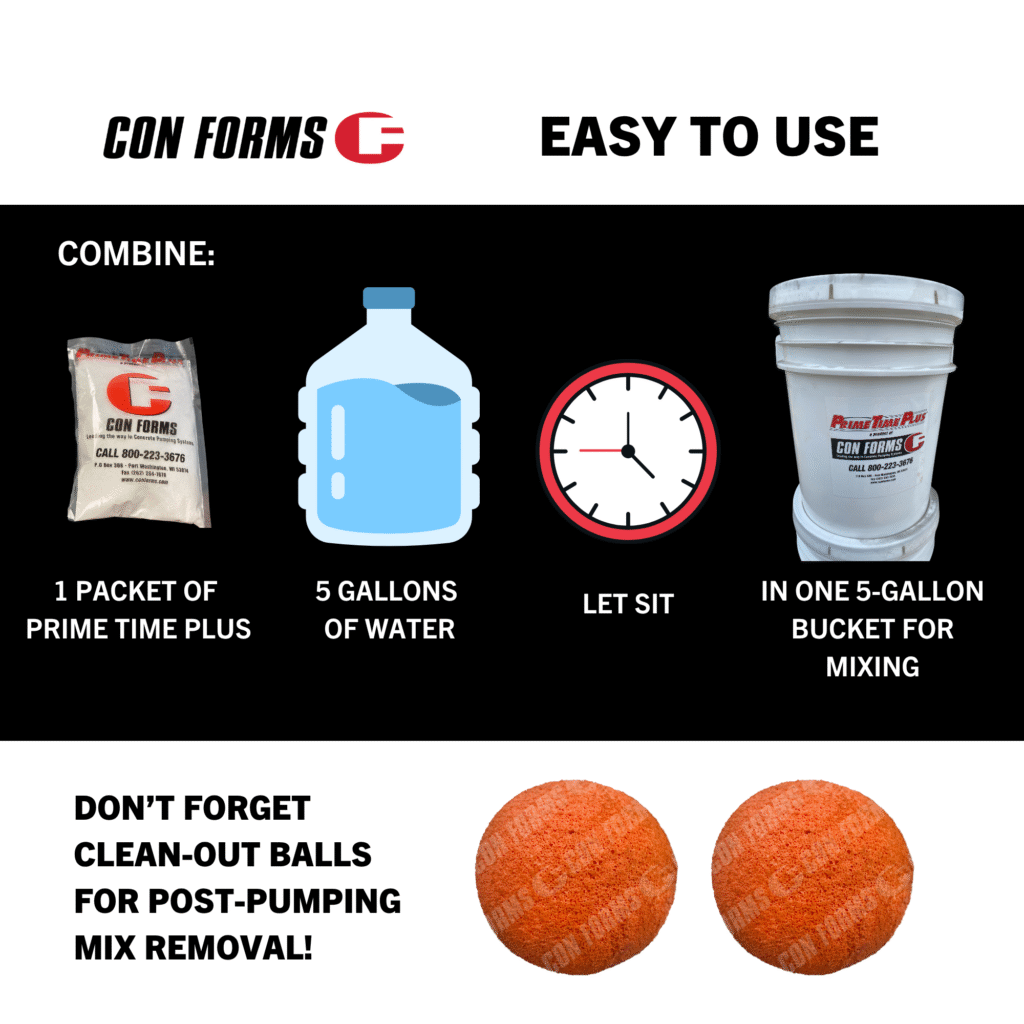

ORDERING INFORMATION

REQUIREMENTS