Business Unit: Con Forms

Market Segment: Civil Engineering / Marine Construction

Company or Customer Name: JF Brennan, Maxon Industries, Yard1, Gordy’s Concrete Pumping

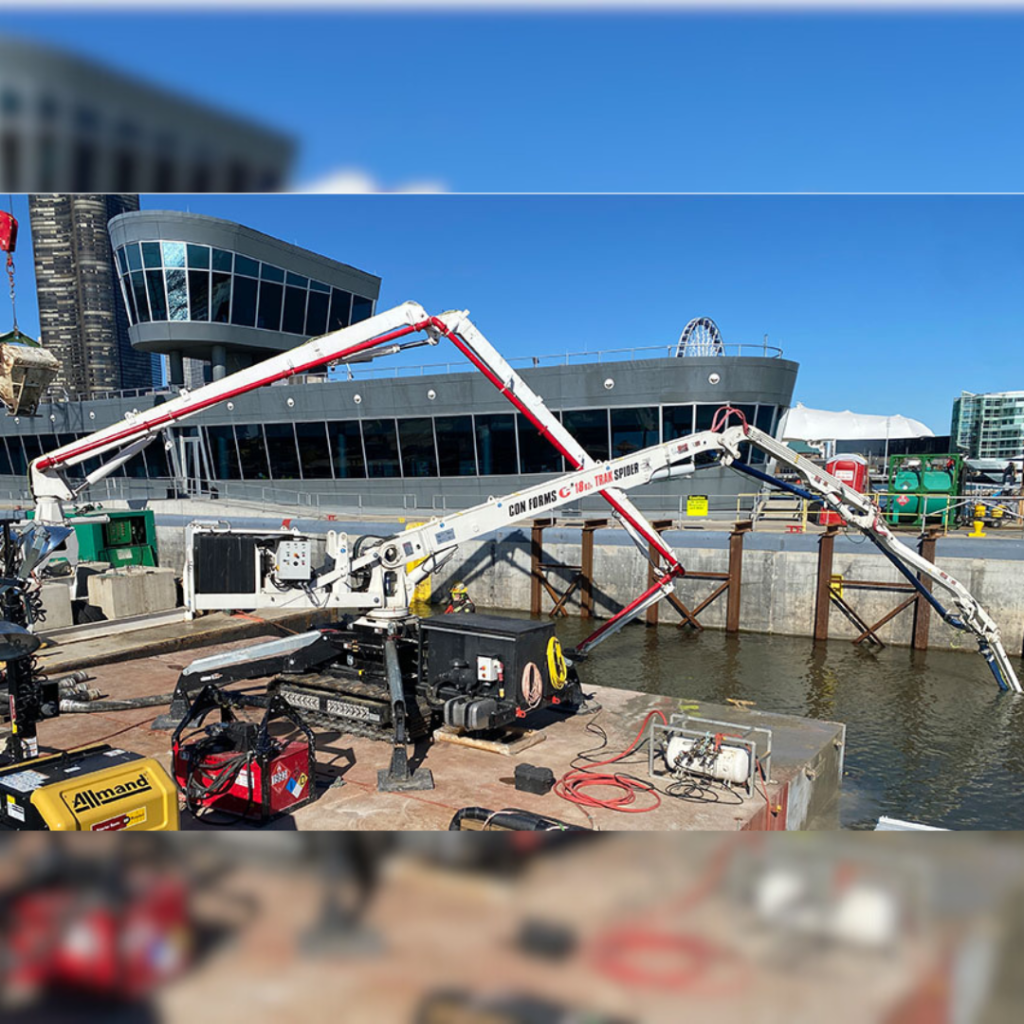

Location of Project: Chicago Harbor Lock

Application: Multiple pump and placing booms for lock wall repair

Environment: Marine placement via barge

Products Used: Con Forms 18RZ4 Spider, additional Con Forms laydown system products

Solution:

Con Forms played a pivotal role in the recent repair of the Chicago Harbor Lock, originally constructed in 1938. Collaborating with four esteemed customers—Maxon, Yard1, JF Brennan, and Gordy’s Concrete Pumping—Con Forms demonstrated its extensive reach and capability to service a diverse clientele.

JF Brennan, a marine construction and dredging expert with longstanding ties to Con Forms and Ultra Tech, spearheaded the project. Yard1, based in Bensenville, Illinois, owns and operates a wide variety of concrete placing equipment including concrete boom trucks, Con Forms Spider and deck placers, and Telebelt conveyors. The Yard1 Telebelt was instrumental in the transfer of concrete from the shore-based hopper into laydown buckets on the placing barge.

These buckets were then barged out to the lock and discharged into the Maxon Industries, 10 cubic yard, Maxcrete agitated concrete hooper. The Maxon Maxcrete’s unique design facilitated rapid offloading and transfer of concrete to the placing barge. Maxon and Con Forms have worked together for over 20 years to develop and perfect the tools required for efficient concrete placement.

Gordy’s Concrete Pumping enhanced the operation with a Con Forms 18RZ4 Spider, operating from the placing barge. This equipment’s design eliminated placement dead zones, maximizing the placement footprint at each setup location.

This project underscores the intricate nature of concrete construction jobs and the collective expertise required for successful completion. Con Forms is proud to contribute to this project and many more vital infrastructure projects around the world.