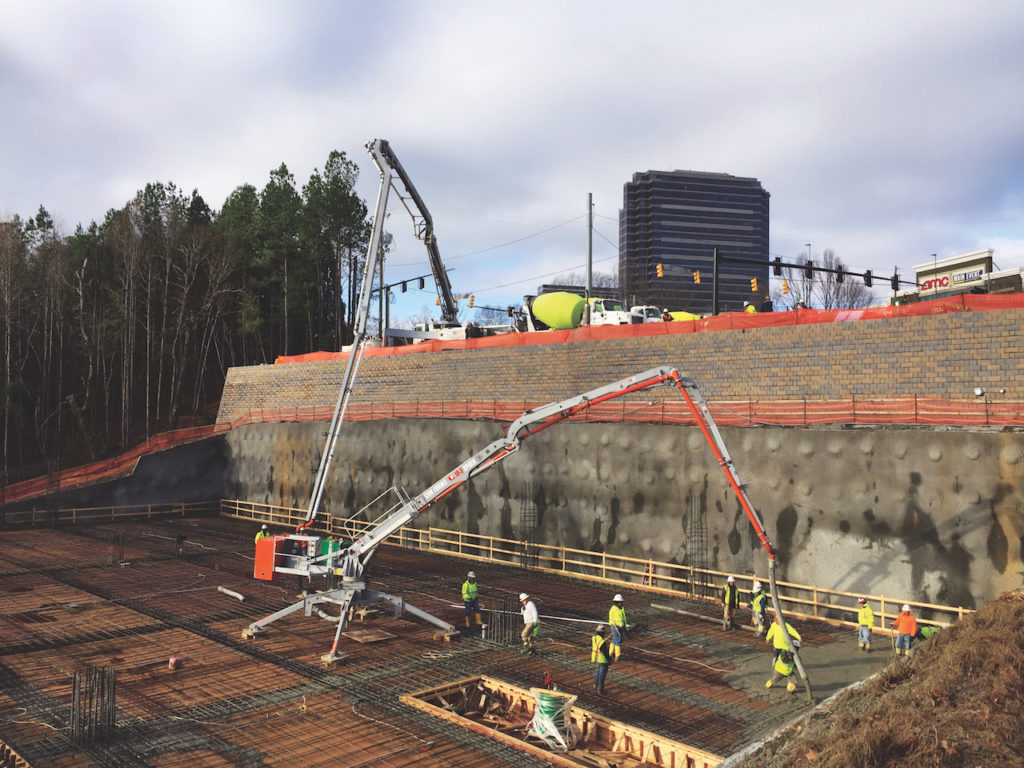

The evolution of the concrete pumping industry continues with a new Spider Boom that extends the reach of conventional truck-mounted boom pumps. Cherokee Pumping, Hampton, GA is using the new Spider Boom from Construction Forms to tackle the large footprint of HD Supply’s new eight-story headquarters and training center in suburban Atlanta. Shell McElroy, Atlanta, is the general contractor building the 8-story structure that also incorporates a six-story subterranean parking garage.

“The large 310-foot by 180-foot footprint of the structure does not provide a lot of access on-site for truck pumps. This posed a challenge which Cherokee met with this new piece of placing equipment,“ explains Jeff Brock, project manager for the general contractor, “And it saved us some money over conventional methods.” Wayne Bylsma, owner of Cherokee, describes the concept of the 18-meter self-standing placing boom, “Imagine adding 59-feet to the tip hose of your boom pump and all of a sudden your 58-meter is a 77-meter.” The ConForms SPH-18-3 on the HD Supply job is a three-section remote control placing boom with CF five-inch heat-treated Ultra III system and boom hose.

“The money saved versus a separate placing boom is significant considering the daily rental rate and virtually no engineering required,” says Brock, “And there are no block-outs for masts.” The large rectangular configuration of the building footprint would have required four mast locations. The tower crane on the project repositions the ConForms Spider Boom. More than 10,900 square-feet can be poured from one location. “Starting out we were repositioning the Spider boom in 30-minutes, but we are now down to 15-minutes,” according to Bylsma. The boom’s name comes from the four articulating hydraulic legs supporting the entire 15,000-pound assembly that includes the boom, balance beam, legs and counterweight.

Ground breaking was June 13, 2016 for the 222,500-square-foot, $100 million HD building, The massive excavation was completed and concrete for the underground parking began in the Fall. The ConForms SPH-18 was lowered into the excavation and Cherokee’s 46-meter boom pump supplied the concrete. Each pour consumed approximately 200 yards before the placing boom was moved. The schedule called for placement of 600-700 yards per day. The six-stories of parking decks, and columns were completed in early Spring and the eight stories of above grade construction is commencing.

The Spider Boom’s legs incorporate pads that rest on wooden platforms on the formed/shored deck around the reinforcing steel. “There is surprisingly very little boom bounce and the Spider boom does not need to be tied down,” according to Bylsma. The 46-meter boom hooks directly into the remote boom’s delivery line or, if necessary, hard line is placed on the deck. “It’s much more efficient to place with the Spider than to drag a hose, “ Bylsma notes. The remote boom also saves money with no fixed system to multiple mast locations. The boom operates off of an electric power pack that supplies the remote boom’s hydraulics. Gas and diesel power packs are available. “We have another Spider boom ordered and it will have a Honda powerpack that will allow us to run off gas or electric power,” he notes.

As the building rises, Cherokee will continue to feed the Spider with a boom pump. “We will be able use the 46 meter boom for the rest of the project. It’s ability to reach up and over will reduce set-ups and allow us to position the pump close to the structure,” according to Bylsma.

John Schantz, Director of R&D at ConForms sees a bright future for the Spider Boom, “It fills the gap between boom pumps and separate placing booms with versatility and mobility.” The company has added a 16-meter four-section Z-fold model with a low 14-foot unfolding height. “This could easily find a place in low overhead situations with our track-mounted option that would allow it to self-propel into tight situations, “ Schantz adds, “We think the market will find lots of uses for the Spider boom that we haven’t even considered.” Both models of the Spider boom can be ordered with tracks powered by diesel, gas or electric engines that also power the hydraulics. The company has delivered seven Spider booms to date with more on the way.

”We conducted an internal audit on the Spider Boom but we will be having a Concrete Pump Manufacturers Association (CPMA) audit performed this summer,” states Schantz. The members of the CPMA are dedicated to supplying equipment and accessories to the concrete pumping industry that meet or exceed the requirements contained in the ASME B30.27 Safety Standard. One requirement of being a CPMA member company is the commitment to undergo a successful completion of an independent audit once every three years. This audit reviews all pertinent sections of the current ASME B30.27 standard and determines if randomly selected representative samples from the manufacturer meet or exceed the necessary criteria.

“As general contractors we have an energetic vision for ‘what’s next’, “ explains Brock, “The Spider is new technology that shortens time to delivery while adding value to the process. We’re in it to build the best project we can, in the most efficient way possible.” The HD Supply site next to Interstate 75 is providing visibility for the new method of concrete placement. The site also gives HD Supply a much different setting where its brand has more visibility and the 900 employees can more easily interact. The company provides a broad range of products and value-added services to approximately 500,000 customers in maintenance, repair and operations, water infrastructure and residential and non-residential construction.

Specs:

Owner: HD Supply, Atlanta, GA

General Contractor: Shell McElroy Constrcution Company LLC, Atlanta, GA

Pumping Contractor: Cherokee Pumping, Hampton, GA

Pumping/Placing Equipment: Construction Forms SPH-18-3 Spider Boom, Schwing S 46 SX concrete pump.